Delivering world’s best-in-class

denim products and services

Raymond’s passion for denim started in 1996 with state-of-the-art denim fabric manufacturing facility, in collaboration with an Italian denim major. In 2006, Raymond entered into a joint venture with Belgian denim major UCO NV with a vision to mark worldwide presence.

Spread over 169 acres, the denim fabric manufacturing facility is strategically located in the heart of the cotton belt in India – city named Yavatmal. With fabric manufacturing capacity of up to 44 Million meters per annum, and 2.75 Million pieces per annum of denim garments this facility today has turned out to be one of the most versatile, flexible and vertically integrated denim manufacturing facility in India.

The company is committed to delivering best-in-class denim products and garmenting related solutions.

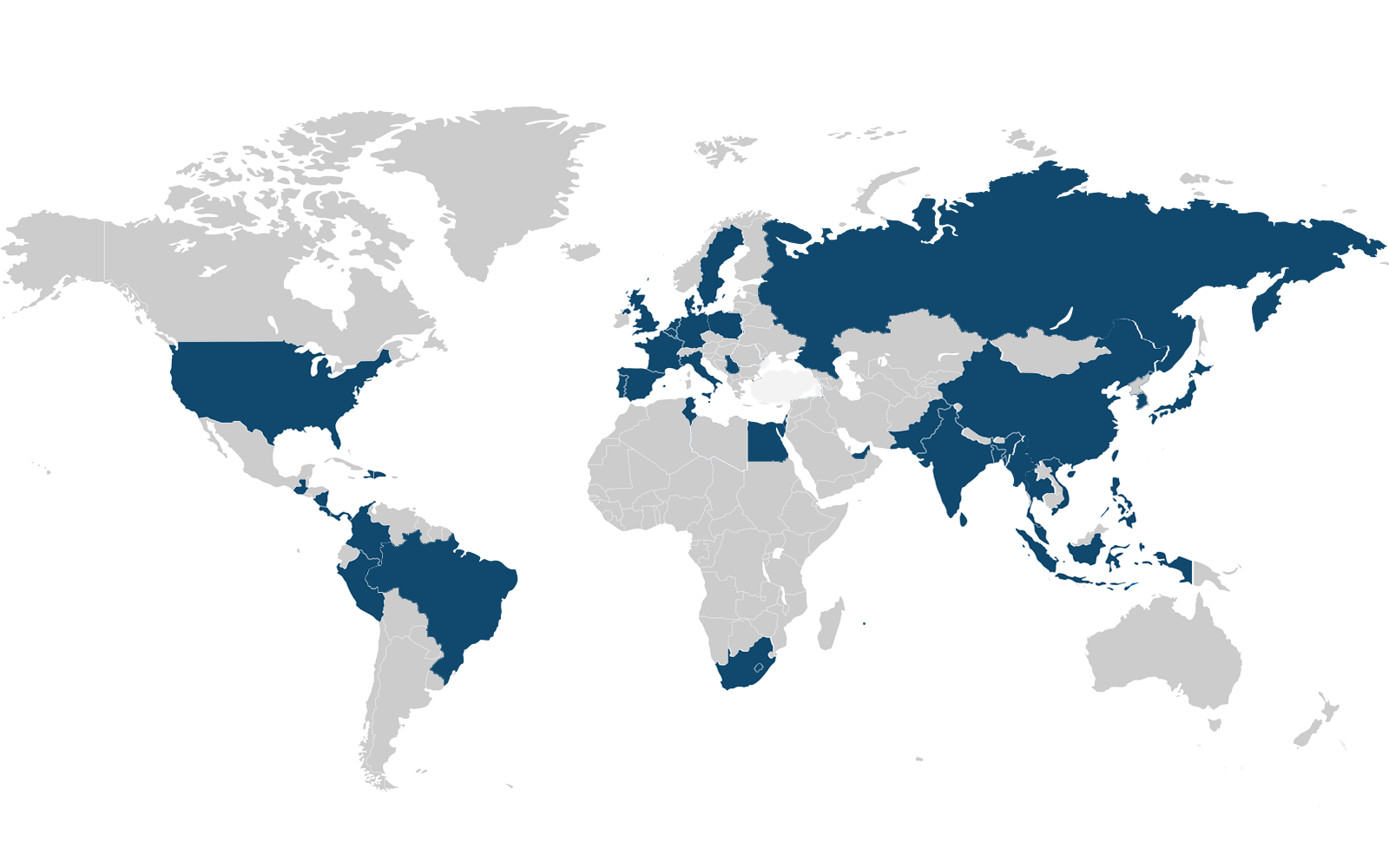

As a trusted and preferred partner for leading global and Indian denim brands, RaymondUCO is scaling its global presence to greater heights in the denim world.